Tyre Knowledge

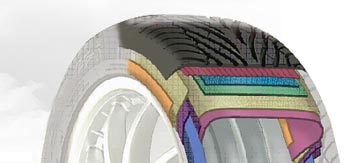

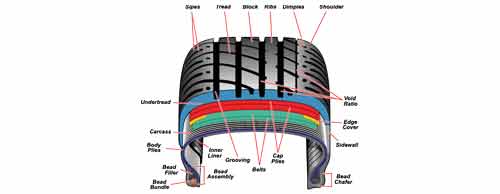

Components of a Tyre

A tire carcass is composed of several parts.

Tread

The tread is that part of the tyre which comes in

contact with the road. The tread is made of thick rubber, or composite

compound formulated to provide an appropriate level of traction that does

not wear away quickly. Tire tread patterns are the arrangement of continuous

ribs, independent tread blocks, circumferential and lateral grooves, as well

as the thin sipes molded into the tread to fine-tune noise, handling,

traction and wear. Tire treads patterns feature different basic designs to

help them meet anticipated driving conditions.

Click

here to enlarge view

Click

here to enlarge view

Bead

The bead is that part of the tire that contacts the rim on

the wheel. The bead is typically reinforced with steel wire and compounded

of high strength, low flexibility rubber. The bead seats tightly against the

two rims on the wheel to ensure that a tubeless tire holds air without

leakage. The bead fit is tight to ensure the tire does not shift

circumferentially as the wheel rotates. The width of the rim in relationship

to the tire is a factor in the handling characteristics of an automobile,

because the rim supports the tire's profile.

Sidewall

The sidewall is that part of the tire that bridges

between the tread and bead. The sidewall is largely rubber but reinforced

with fabric or steel cords that provide for strength and flexibility. The

sidewall transmits the torque applied by the drive axle to the tread in

order to create traction. The sidewall, in conjunction with the air

inflation, also supports the load of the vehicle. Sidewalls are molded with

manufacturer-specific detail, government mandated warning labels, and other

consumer information.

Shoulder

The shoulder is that part of the tire at the edge

of the tread as it makes transition to the sidewall.

Ply

Plies are layers of relatively inextensible cords

embedded in the rubber to hold its shape by preventing the rubber from

stretching in response to the internal pressure. The orientations of the

plies plays a large role in the performance of the tire and is one of the

main ways that tires are categorized. The number of plies determines the

load capacity of the tyre.

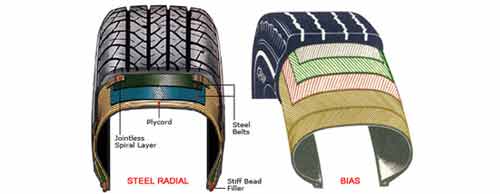

Construction Types

Bias

Bias tire (or cross ply) construction utilizes body ply cords

that extend diagonally from bead to bead, usually at angles in the range of

30 to 40 degrees, with successive plies laid at opposing angles forming a

crisscross pattern to which the tread is applied. The design allows the

entire tire body to flex easily, providing the main advantage of this

construction, a smooth ride on rough surfaces. This cushioning

characteristic also causes the major disadvantages of a bias tire: increased

rolling resistance and less control and traction at higher speeds.

Click

here to enlarge view

Click

here to enlarge view

Belted Bias

A belted bias tire starts with two or more bias-plies to

which stabilizer belts are bonded directly beneath the tread. This

construction provides smoother ride that is similar to the bias tire, while

lessening rolling resistance because the belts increase tread stiffness. The

plies and belts are at different angles, which improves performance compared

to non-belted bias tires. The belts may be cord or steel.

Radial

Radial tire construction utilizes body ply cords extending from the beads

and across the tread so that the cords are laid at approximately right

angles to the centerline of the tread, and parallel to each other, as well

as stabilizer belts directly beneath the tread. The belts may be cord or

steel. The advantages of this construction include longer tread life, better

steering control, and lower rolling resistance. Disadvantages of the radial

tire include a harder ride at low speeds on rough roads and in the context

of off-roading, decreased "self-cleaning" ability and lower grip

ability at low speeds.

Solid

Many tires used in industrial and commercial applications are

non-pneumatic, and are manufactured from solid rubber and plastic compounds

via molding operations.

Solid tires include those used for

lawn mowers, skateboards, golf carts, scooters, and many types of light

industrial vehicles, carts, and trailers. One of the most common

applications for solid tires is for material handling equipment (forklifts).

Such tires are installed by means of a hydraulic tire press.

Specifications

Tire pressure monitoring system

Tire pressure monitoring systems (TPMS) are electronic systems that monitor

the tire pressures on individual wheels on a vehicle, and alert the driver

when the pressure goes below a warning limit. There are several types of

designs to monitor tire pressure. Some actually measure the air pressure,

and some make indirect measurements, such as gauging when the relative size

of the tire changes due to lower air pressure.

Inflation pressure

Tires are specified by the vehicle manufacturer with a recommended

inflation pressure, which permits safe operation within the specified load

rating and vehicle loading. Most tires are stamped with a maximum pressure

rating. For passenger vehicles and light trucks, the tires should be

inflated to what the vehicle manufacturer recommends, which is usually

located on a decal just inside the driver's door or in the vehicle owners

handbook. Tires should not generally be inflated to the pressure on the

sidewall; this is the maximum pressure, rather than the recommended

pressure.

Load rating

Tires are specified by the manufacturer with a maximum load rating. Loads

exceeding the rating can result in unsafe conditions that can lead to

steering instability and even rupture.

Speed rating

The speed rating denotes the maximum speed at which a tire is designed to

be operated. For passenger vehicles these ratings range from 99 to 186 miles

per hour (159 to 299 km/h). Replacing a tire on a vehicle with one with a

lower speed rating than originally specified by the vehicle manufacturer may

render the insurance invalid.

Retread

Tires that are fully worn can be re-manufactured to replace the worn tread.

This is known as retreading or recapping, a process of buffing away the worn

tread and applying a new tread. Retreading is economical for truck tires

because the cost of replacing the tread is less than the price of a new

tire. Retreading passenger tires is less economical because the cost of

retreading is high compared to the price of new cheap tires, but favorable

compared to high-end brands.

Markings

DOT code

In the United States, the DOT Code is an alphanumeric character

sequence molded into the sidewall of the tire for purposes of tire

identification. The DOT Code is mandated by the U.S. Department of

Transportation. The DOT Code is useful in identifying tires in a product

recall.

E-mark

All tires sold for road use in Europe after July 1997 must carry an E-mark.

The mark itself is either an upper case "E" or lower case "e" -

followed by a number in a circle or rectangle, followed by a further number.

An (upper case) "E" indicates that the tire is certified to comply

with the dimensional, performance and marking requirements of ECE regulation

30. A (lower case) "e" indicates that the tire is certified to

comply with the dimensional, performance and marking requirements of

Directive 92/23/EEC.

Safety

Proper vehicle safety requires specific attention to inflation pressure,

tread depth, and general condition of the tires. Over-inflated tires run the

risk of explosive decompression (they may pop). On the other hand,

under-inflated tires have a higher rolling resistance and suffer from

overheating and rapid tread wear particularly on the edges of the tread.

Excessive tire wear will reduce steering and braking response, and

tires worn down past their safety margins and into the casing run the very

real risk of rupturing.

Hydroplaning (or aquaplaning)

Hydroplaning, also known as aquaplaning, is the condition where a layer of

water builds up between the tire and road surface. Hydroplaning occurs when

the tread pattern cannot channel away enough water at an adequate rate to

ensure a semi-dry footprint area. When hydroplaning occurs, the tire

effectively "floats" above the road surface on a cushion of water -

and loses traction, braking and steering, creating a very unsafe driving

condition. When hydroplaning occurs, there is considerably less

responsiveness of the steering wheel. The correction of this unsafe

condition is to gradually reduce speed, by merely lifting off the

accelerator/gas pedal.

Scrap tires and environmental issues

Once tires are discarded, they are considered scrap tires. Scrap tires

are often re-used for things from bumper car barriers to weights to hold

down tarps. Some facilities are permitted to recycle scrap tires through

chipping, and processing into new products, or selling the material to

licensed power plants for fuel. Some tires may also be retreaded for re-use.

One group did "a study to evaluate the possibility of using scrap tires

as a crash cushion system. The objective of this study was to evaluate the

material properties of used tires and recycled tire-derived materials for

use in low-cost, reusable crash cushions".